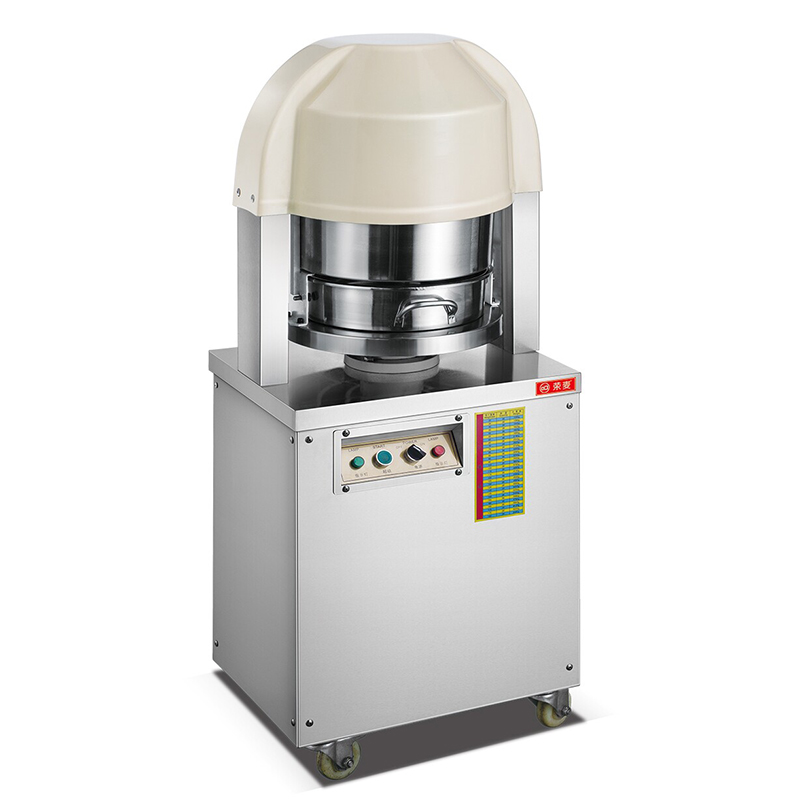

Freanch Bread Dough Baguette Moulder Machine Bakery Equipment For Sale

Name: French Roll Moulder

Dough weight: 50-1250 g

Output: approx 1200 pieces of dough per hour

Voltage: AC220V/AC380V

Speed of the front conveying belt: 46m/min.

Specification of the back conveying belt: perimeter 1292mm. width 730mm. thickness 8mm

Speed of the back conveying belt: 39m/min.

Adjustable distance of the conveying board: 0-41mm

Adjustable clearance of the dough press roller: 0-19 mm

Conveying board adjustable size: 0-41mm

press roller adjustable gap:0-19 mm

Product Overview of Baguette Moulder machine

Product Overview of Baguette Moulder machine

Baguette Moulder is the special dough Moulder for bread making which can roll press, roll up and rub and can shape dough in sticks.It is mainly applied to shape French loaf. It is also applied to shape toast and baguette.Baguette Moulder can meet your shape requirements after rolling press and rubbing dough according to the diameter and length of your products. From dough weight 50g to 1250g. About 1200 pieces an hour can be produced.Baguette Moulder has easy operation and high efficiency ,which is a good helper for making bread.

Specification of French bread Moulder bakery equipment

Name: French Roll Moulder

Dough weight: 50-1250 g

Output: approx 1200 pieces of dough per hour

Voltage: AC220V/AC380V

Speed of the front conveying belt: 46m/min.

Specification of the back conveying belt: perimeter 1292mm. width 730mm. thickness 8mm

Speed of the back conveying belt: 39m/min.

Adjustable distance of the conveying board: 0-41mm

Adjustable clearance of the dough press roller: 0-19 mm

Conveying board adjustable size: 0-41mm

press roller adjustable gap:0-19 mm

| Model | TYPE | Voltage | Power (kw) | Capacity | Size (mm) | Weigh |

| RMZ-750 | Baguette Moulder | 220/380V | 1 | 50-1250g | 970x1100x1600 | 290 |

Advantages of Baguette Moulder machine

Knob adjuster with calibration indication, flexible and accurate setting

Roller is food grade material, roll pressure evenly distributed

Roller is food grade material, roll pressure evenly distributed

Adjustable feet & universal wheel.Easy to move, stand steady.

French bread machine Theory instruction

The motor passes the power to the dough press roller and conveying belt rollers through triangle belt. The dough press roller conveys by chain wheel and the roller clearance is adjustable (0-19mm) . Use the hand wheel with a counter on the left side of the machine to adjust. Then, it press dough into strips.

Conveying belt rollers are installed respectively on the front and back conveying boards. The adjustable space range between two boards is 1- 41mm.

Dough strips rise along the front conveying board. They are covered by the cloth with press roll. Now the procedure of first stick rubbing begins. When the first rubbed dough sticks rise to the top. they drop down between the front and the back material conveying boards.

The second stick rubbing procedure begins because of the speed difference between the front and the back conveying belts. Dough sticks turn long and tight and drop into the receiving plate at last.

The distance between the front and the back feed-boards is adjusted by the hand wheel with a counter on the right side of the machine, then, you can control the length of dough sticks.

Our Service

1.To satisfy one-stop convenience for our client, our company presented service of matching kitchen equipment.

2.We offers OEM & ODM services. Our company has strong ability to design and manufacture, with more than 13 years of business experience.

3.Customized according to the different needs of customers, such as the energy consumption of diesel, electric and gas.

4.We can offer the spare parts according to your order. One year warranty.

5.You have flexibility to choose the payment terms that work best for your budget.

6. We offers profession consultancy and solution to customers.

7. Packed in protective wooden case to ensure the safety of transportation. All our product can be packed as you need.

8.With CE & ISO9001 certification.

8.Factory direct sale price. Quality assurance.

Seng Inquiry To Us

- Product Details

-

Product Overview of Baguette Moulder machine

Product Overview of Baguette Moulder machine

Baguette Moulder is the special dough Moulder for bread making which can roll press, roll up and rub and can shape dough in sticks.It is mainly applied to shape French loaf. It is also applied to shape toast and baguette.Baguette Moulder can meet your shape requirements after rolling press and rubbing dough according to the diameter and length of your products. From dough weight 50g to 1250g. About 1200 pieces an hour can be produced.Baguette Moulder has easy operation and high efficiency ,which is a good helper for making bread.

Specification of French bread Moulder bakery equipment

Name: French Roll Moulder

Dough weight: 50-1250 g

Output: approx 1200 pieces of dough per hour

Voltage: AC220V/AC380V

Speed of the front conveying belt: 46m/min.

Specification of the back conveying belt: perimeter 1292mm. width 730mm. thickness 8mm

Speed of the back conveying belt: 39m/min.

Adjustable distance of the conveying board: 0-41mm

Adjustable clearance of the dough press roller: 0-19 mm

Conveying board adjustable size: 0-41mm

press roller adjustable gap:0-19 mm

Model TYPE Voltage Power (kw) Capacity Size (mm) Weigh RMZ-750 Baguette Moulder 220/380V 1 50-1250g 970x1100x1600 290 Advantages of Baguette Moulder machine

Knob adjuster with calibration indication, flexible and accurate setting

Roller is food grade material, roll pressure evenly distributed

Roller is food grade material, roll pressure evenly distributed

Adjustable feet & universal wheel.Easy to move, stand steady.

French bread machine Theory instruction

The motor passes the power to the dough press roller and conveying belt rollers through triangle belt. The dough press roller conveys by chain wheel and the roller clearance is adjustable (0-19mm) . Use the hand wheel with a counter on the left side of the machine to adjust. Then, it press dough into strips.

Conveying belt rollers are installed respectively on the front and back conveying boards. The adjustable space range between two boards is 1- 41mm.

Dough strips rise along the front conveying board. They are covered by the cloth with press roll. Now the procedure of first stick rubbing begins. When the first rubbed dough sticks rise to the top. they drop down between the front and the back material conveying boards.

The second stick rubbing procedure begins because of the speed difference between the front and the back conveying belts. Dough sticks turn long and tight and drop into the receiving plate at last.

The distance between the front and the back feed-boards is adjusted by the hand wheel with a counter on the right side of the machine, then, you can control the length of dough sticks.

- Service

-

Our Service

1.To satisfy one-stop convenience for our client, our company presented service of matching kitchen equipment.

2.We offers OEM & ODM services. Our company has strong ability to design and manufacture, with more than 13 years of business experience.

3.Customized according to the different needs of customers, such as the energy consumption of diesel, electric and gas.

4.We can offer the spare parts according to your order. One year warranty.

5.You have flexibility to choose the payment terms that work best for your budget.

6. We offers profession consultancy and solution to customers.

7. Packed in protective wooden case to ensure the safety of transportation. All our product can be packed as you need.

8.With CE & ISO9001 certification.

8.Factory direct sale price. Quality assurance. - Contact

-

Seng Inquiry To Us