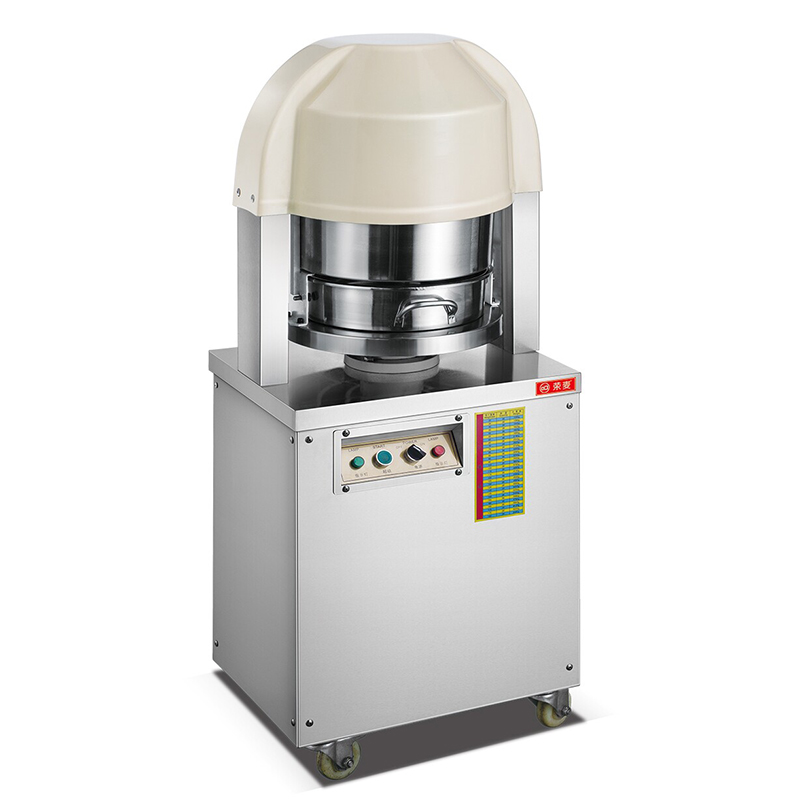

Commercial Hydraulic Dough Divider Machine For Sale

Usage of commercial hydraulic dough divider

The Hydraulic dough Divider can be used to divide large dough into 20pcs or 16pcs same weight division, and the inside structure is close-grained. It can use as the pizza dough divider and bread dough divider machine.It can save labour cost and avoid division difference by hand.

Advantages of hydraulic dough divider

1.Divide large dough into 20pcs same weight division.Operate easily.

2.Save time, only 10~20seconds per operating time for large production.

3.Clean easily.Machine strong with long life.

Commercial hydraulic dough divider

Usage of commercial hydraulic dough divider

The Hydraulic dough Divider can be used to divide large dough into 20pcs or 16pcs same weight division, and the inside structure is close-grained. It can use as the pizza dough divider and bread dough divider machine.It can save labour cost and avoid division difference by hand.

Advantages of hydraulic dough divider

1.Divide large dough into 20pcs same weight division.Operate easily.

2.Save time, only 10~20seconds per operating time for large production.

3.Clean easily.Machine strong with long life.

Specification and Technician Data

| Model | Capacity(Pcs) | Voltage | Power (kw) | Dividing Range | Size (mm) |

| RMK-16H | 16Pcs | 220V/380V | 0.75 WK | 100-800g | 610x680x1000 mm |

| RMK-20H | 20Pcs | 220V/380V | 0.75 WK | 125-1000g | 610x680x1000 mm |

Installation of bread dough divider machine

- Choose dry, flat floor without direct sunshine and hot source

- Connect the correct power supply with 380V+N+PE, and 3hase, 10A breaker.

- Open the cover, take out 4pcs plastic tube, use vegetable oil to clean the surface of the cutter and pump.

Operation

- Connect the power supply and need to connect with ground.

- Push the “down” button to move the cutter base and cutter to lowest position, put some vegetable oil on the surface.

- Load the dough(Max weight 16kgs), and put some vegetable oil on the dough surface.

- Close the top cover, tighten the top handle.

- Push the “up” button to finish pressing, dividing.

- Open the cover, push “down” button to raise cutter base, and take out the division dough.

Cleaning and Maintenance

- After usage, you should clean the pump, cutter base, cutter, inside surface of top cover..

- Use cloth to dip vegetable oil to clean. Please use sunflower oil, olive oil. Salad oil not allowed.

RFQ of hydraulic bread dough divider

Q1:What should noted during operation?

A1:Note: 1.Weight depends on the dough condition, Less weight, lower quality of side. Dough cant be too soft or hard, otherwise, the quality is not good.

2.Cut off power supply when loading, taking out dough, and cleaning.

3.Use correct hydraulic oil and clean vegetable oil.

4.4 pcs plastic tubes for cleaning not allowed to put on the cutter.

Q2:How to clean the dough cutter base and cutter?

A2:Open the top cover, put 4 plastic tubes upright on the surface of the cutter base. Note: it can’t be put on the cutter.Close the top cover, push “up” button to raise the cutter, while the cutter base on the lowest position, and the cutter on the highest position, then cut off power supply, open the cover, clean the cutter and cutter base.

1.Every week, please clean the machine outside with sponge with soap water, not directly by water.

2.Every week, please clean machine inside. Pull the machine, cleaning same as cutter and cutter base, let the cutter base on the lowest position, cutter on the highest position. Open the side panel, you can see the machine inside. Cut off power supply, use brush to clean all corners to remove the dough and flour.

3.Every 3 months check the hydraulic oil meter of hydraulic unit.Let he cutter base, cutter to the lowest position, cut off power supply, then pull the machine, open the side panel, and you can see the hydraulic unit. Open the lid of hydraulic unit, use oil meter or clean screwdriver to check if there is 2cm oil, if less, you have to add more.

Our Service

1.To satisfy one-stop convenience for our client, our company presented service of matching kitchen equipment.

2.We offers OEM & ODM services. Our company has strong ability to design and manufacture, with more than 13 years of business experience.

3.Customized according to the different needs of customers, such as the energy consumption of diesel, electric and gas.

4.We can offer the spare parts according to your order. One year warranty.

5.You have flexibility to choose the payment terms that work best for your budget.

6. We offers profession consultancy and solution to customers.

7. Packed in protective wooden case to ensure the safety of transportation. All our product can be packed as you need.

8.With CE & ISO9001 certification.

8.Factory direct sale price. Quality assurance.

Seng Inquiry To Us

- Product Details

-

Commercial hydraulic dough divider

Usage of commercial hydraulic dough divider

The Hydraulic dough Divider can be used to divide large dough into 20pcs or 16pcs same weight division, and the inside structure is close-grained. It can use as the pizza dough divider and bread dough divider machine.It can save labour cost and avoid division difference by hand.

Advantages of hydraulic dough divider

1.Divide large dough into 20pcs same weight division.Operate easily.

2.Save time, only 10~20seconds per operating time for large production.

3.Clean easily.Machine strong with long life.

Specification and Technician Data

Model Capacity(Pcs) Voltage Power (kw) Dividing Range Size (mm) RMK-16H 16Pcs 220V/380V 0.75 WK 100-800g 610x680x1000 mm RMK-20H 20Pcs 220V/380V 0.75 WK 125-1000g 610x680x1000 mm Installation of bread dough divider machine

- Choose dry, flat floor without direct sunshine and hot source

- Connect the correct power supply with 380V+N+PE, and 3hase, 10A breaker.

- Open the cover, take out 4pcs plastic tube, use vegetable oil to clean the surface of the cutter and pump.

Operation

- Connect the power supply and need to connect with ground.

- Push the “down” button to move the cutter base and cutter to lowest position, put some vegetable oil on the surface.

- Load the dough(Max weight 16kgs), and put some vegetable oil on the dough surface.

- Close the top cover, tighten the top handle.

- Push the “up” button to finish pressing, dividing.

- Open the cover, push “down” button to raise cutter base, and take out the division dough.

Cleaning and Maintenance

- After usage, you should clean the pump, cutter base, cutter, inside surface of top cover..

- Use cloth to dip vegetable oil to clean. Please use sunflower oil, olive oil. Salad oil not allowed.

RFQ of hydraulic bread dough divider

Q1:What should noted during operation?

A1:Note: 1.Weight depends on the dough condition, Less weight, lower quality of side. Dough cant be too soft or hard, otherwise, the quality is not good.

2.Cut off power supply when loading, taking out dough, and cleaning.

3.Use correct hydraulic oil and clean vegetable oil.

4.4 pcs plastic tubes for cleaning not allowed to put on the cutter.

Q2:How to clean the dough cutter base and cutter?

A2:Open the top cover, put 4 plastic tubes upright on the surface of the cutter base. Note: it can’t be put on the cutter.Close the top cover, push “up” button to raise the cutter, while the cutter base on the lowest position, and the cutter on the highest position, then cut off power supply, open the cover, clean the cutter and cutter base.

1.Every week, please clean the machine outside with sponge with soap water, not directly by water.

2.Every week, please clean machine inside. Pull the machine, cleaning same as cutter and cutter base, let the cutter base on the lowest position, cutter on the highest position. Open the side panel, you can see the machine inside. Cut off power supply, use brush to clean all corners to remove the dough and flour.

3.Every 3 months check the hydraulic oil meter of hydraulic unit.Let he cutter base, cutter to the lowest position, cut off power supply, then pull the machine, open the side panel, and you can see the hydraulic unit. Open the lid of hydraulic unit, use oil meter or clean screwdriver to check if there is 2cm oil, if less, you have to add more.

- Service

-

Our Service

1.To satisfy one-stop convenience for our client, our company presented service of matching kitchen equipment.

2.We offers OEM & ODM services. Our company has strong ability to design and manufacture, with more than 13 years of business experience.

3.Customized according to the different needs of customers, such as the energy consumption of diesel, electric and gas.

4.We can offer the spare parts according to your order. One year warranty.

5.You have flexibility to choose the payment terms that work best for your budget.

6. We offers profession consultancy and solution to customers.

7. Packed in protective wooden case to ensure the safety of transportation. All our product can be packed as you need.

8.With CE & ISO9001 certification.

8.Factory direct sale price. Quality assurance. - Contact

-

Seng Inquiry To Us